- Marine Geotechnics

- Marine Geotechnics Lab

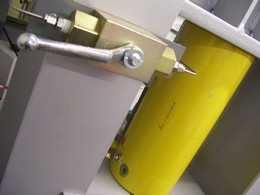

- Heated uniaxial apparatus

Heated uniaxial apparatus

Basically, an apparatus consists of two principal parts: a hydraulic system and an uniaxial consolidation cell.

A special hydraulic system setup has been adjusted for each apparatus to create the required vertical forces, consisting of a load frame, a high tonnage cylinder (HZB), and a power unit. The power units in use are an ISCO 500D and an ISCO 100DX high precision syringe pump. The unique feature of these pumps is the extremely slow flow rate. Combined with the HZB hydraulic cylinder this arrangement generates particularly small vertical displacements.

The actual deformation of the specimen occurs in the uniaxial consolidation cell. The cell consists of two pistons at either end of the sample. The lower piston is arrested at the base plate of the load frame, while the upper piston is steadily moving downward to apply increasing normal loads onto the sample. This rather simple design is particularly useful to remove the compacted sediment pucks in a non-destruction way after the tests by pushing the pistons through the entire length of the cylinder. For heated tests, the consolidation cell is additionally equipped with a band heater which is wrapped around the cell. The heater is capable of maximum temperatures of 200°C.

For the proposed investigation of the physical and chemical processes in the specimen, both pistons are equipped with boreholes to get access to the sample. To minimize interaction of the saturated sample with the equipment, the consolidation cell was made of titanium (grade 2). Other components such as tubing and fittings also consist of non-corrosive materials like high-grade stainless steel, PTFE, or PP.

The alteration of mechanical properties such as permeability, void ratio and porosity can be determined by the change of deformation and pore water pressure throughout the tests. The deformation is measured by a displacement transducer. Two pressure transducers, mounted to the bottom and the top of the cell, measure the pore water pressure gradient in the cell. All data are logged by a self-adjusted computer program which also functions as a control unit for the pump. At the moment, consolidation tests are conducted as constant-rate of strain tests (CRS).

Components

- 2 independent hydraulic systems

- Hydraulic pump

- PC for evaluation

Characteristics

Hydrauliksystem A

- Power Unit: 100DX

- Maximum force: 915kN

- Minimum throughput: 0,00001 ml/min

- Minimum vertical change in position: 0,0004 mm/day

Hydraulic system B

- Power Unit: 500D

- Maximum force: 343 kN

- Minimum throughput: 0,001 ml/min

- Minimum vertical change in position: 0,04 mm/day

Consolidation cell

- Sample diameter: 63 mm

- Initial sample hight: 100 mm

- Maximum burden applied by 500D: 110 MPa

- Maximum burden applied by 100DX: 296 MPa

Hüpers, A., & Kopf, A. J. (2012). Effect of smectite dehydration on pore water geochemistry in the shallow subduction zone: An experimental approach. Geochemistry, Geophysics, Geosystems, 13(10).