- Home

- Research

- Expeditions

- 2024

- MSM125

MSM125

Project EqTest-GoC

30.01. – 06.02.2024

Algeciras (Spain) – Funchal (Madeira, Portugal)

|

Dr. Christian Borowski (Chief-Scientist) |

|

|

Phone: |

|

|

Dr. Thomas Pape (Co-Chief Scientist, DAPC III) |

|

|

Phone: |

|

|

Dr. Jan Kleint (ISMS & fDOM) |

|

|

Phone: |

|

Objectives

The aim of expedition MSM125 in the Gulf of Cádiz was to test two instruments newly developed at MARUM for analysing gas composition and quantity, as well as a recently purchased sensor for detecting fluorescent dissolved organic matter (fDOM) under deep-sea conditions. Ship time was allocated by the Review Panel German Research Vessels and and a large part of the funds for container transport, travel and daily allowances were made available through the incentive funds of the Cluster of Excellence 'The Ocean Floor - Earth's Uncharted Interface'.

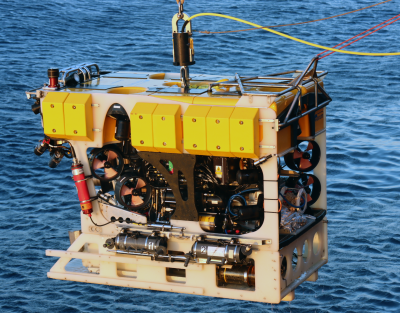

The in situ-mass spectrometer (ISMS) is used to measure dissolved gas concentrations (e.g. CH4, H2S, CO2, O2) at deep-sea hydrothermal vents and hydrocarbon seeps at depths down to 4500 m and temperatures down to 350°C. The ISMS is suitable for deep-sea ROV (remotely operated vehicles) deployments. During MSM125, its integration as a 'heavy payload' in the ROV MARUM SQUID was tested in addition to its function.

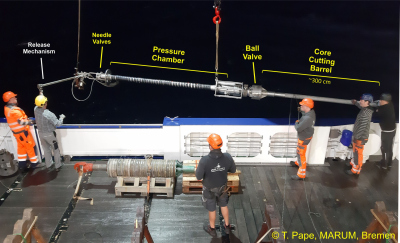

The newly built Dynamic Autoclave Piston Corer III is used to recover in situ-pressurised sediment cores on board the research vessel without losing the free gas phase during the ascent from depth. These up to 3m-long pressurised cores enable the exact quantification of dissolved and free gases or gas hydrates in deep-sea sediments. During MSM125, the pressure resistance of the overall system, its behaviour during sediment sampling and its handling during deployment and preparation and follow-up were to be tested in particular.

The fDOM sensor is suitable for ROV deployments in the deep sea (<6000m) and thus provides real-time information and guidance for water and sediment sampling during field campaigns.

Participating Institutions

Max Planck Institute for Marine Microbiology, Bremen

MARUM - Center for Marine Environmental Sciences, University of Bremen

Department of Geosciences, University of Bremen

University of the Azores, Portugal

Université Hassan II, Casablanca, Morocco

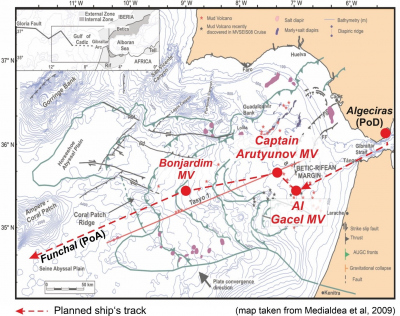

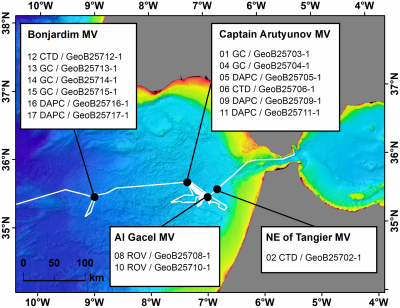

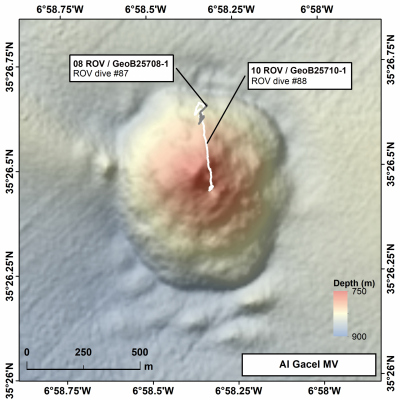

Working Area

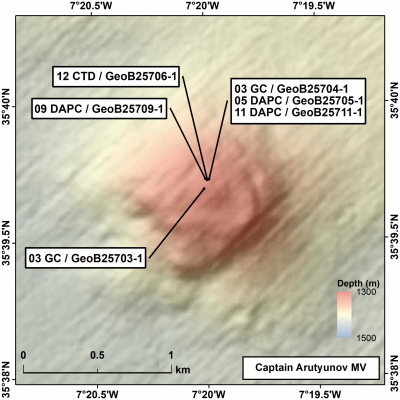

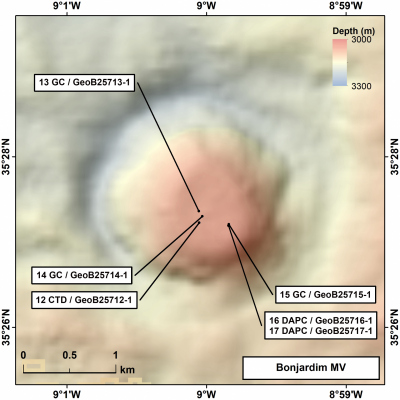

The three mud volcanoes (MVs), Al Gacel MV (775 m water depth), Captain Arutyunov MV (1320 m), and Bonjardim MV (3060 m), were selected as test areas due to the discovery of gas seeps and gas hydrate deposits during previous expeditions. This made them ideal for testing the ISMS and DAPC III at varying water depths. The instruments were tested during several deployments over four working days with different settings and at different water depths. The test results are used to modify and adjust the instruments, forming the basis for successful scientific ship expeditions.

Prior to deploying the equipment, the ship's hydroacoustic systems were used to map the seabed at the mud volcanoes at high resolution. Additionally, the overlying water column was scanned for rising gas bubbles. The ship's CTD/water sampler system was also utilized to determine the physico-chemical parameters in the water column and obtain water samples.

In situ-mass spectrometer (ISMS)

One aim of this equipment test cruise was (i) a technical proof of concept that MARUM ROV SQUID can be used as a platform for payloads that exceed the vehicle default specifications, (ii) the development of work-flows and operational procedures for the ISMS during the dives, and (iii) determining the final design of the ISMS with respect to the installation and handling on ROV systems.

During the dives, several peripheral devices (e.g. flow sensor, pH sensor, and in-situ calibration unit) were tested. Although early attempts with prototypes during cruises MSM109 and M190 were promising, they were not yet satisfactory. Based on these experiences, the initial prototypes underwent significant modifications. Minor problems that occurred during the first dive were resolved, and the devices operated without any issues during the second dive with MARUM ROV SQUID.

The experience and information gathered during this cruise will be used to establish this payload as a standard tool for ROVs, mostly ROVs SQUID and the new QUEST 5000. Furthermore, the option to use such payloads on a smaller ROV system with a small deck footprint, small crew, and smaller logistical efforts compared to full-size work-class ROVs, will be of great value to the scientific community.

© Christian Borowski

Dynamic Autoclave Piston Corer (DAPC) III

DAPC III was tested three times at the Captain Arutyunov MV and twice at the Bonjardim MV at in situ-hydrostatic pressures of approximately 130 and 305 bar.

The current geological and geochemical situation at the target locations was checked in advance using a gravity corer. The cores from both the Captain Arutyunov MV and the Bonjardim MV consisted of a typical mud breccia. Some of these cores contained gas hydrate platelets or pieces, so these locations were used as target positions for the DAPC III deployment

In four of the five DAPC III deployments, a sediment core was recovered under pressure while testing different system settings. The average core recovery from these deployments was 85.4%. In one of the deployments, a ball valve used to seal the pressurised core was not closed immediately after sediment sampling. As a result, lower parts of the sediment core were pushed out of the core liner due to increasing gas expansion during retrieval.

In summary, the MSM125 test cruise provided important insights into the functionality and uptime of the new DAPC III in the deep sea, which could not have been achieved with the technical capabilities available onshore or during cruises in shallow coastal areas. The largely successful operations during MSM125 demonstrated that the new DAPC III is ready for future scientific expeditions.

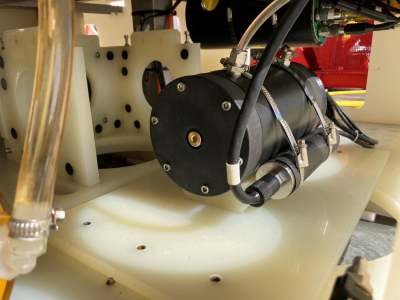

fDOM sensor

During this cruise, an optical single channel fluorometer (ECO FL, Seabird Scientific) was tested under in situ- conditions. The fluorometer is designed to detect fluorescent dissolved organic matter (fDOM) in water depths of up to 6000m. To ensure location-specific measurements, the new sensor was integrated into the tubing of the sampling system. The inlet of the tubing is guided by the ROV's manipulator to the point of sampling. The development and fabrication of a specific flow cell were necessary for this integration.

The flow cell was tested along with the in situ-MS during the dives. Additionally, the fDOM sensor was tested during three CTD casts as it is easy to connect to the CTDs that are currently used by the German research fleet. The performance of the fDOM sensor will be tested by comparing the data with DOM analyses of samples taken with the CTD/rosette after the cruise.