- Startseite

- Jan Kleint

- Fluid Sampling System

Fluid Sampling System

Project Goal: trace-metal clean and/or isobaric fluid sampling (gas-tight) as well as a filtration system during ROV dives

Overview

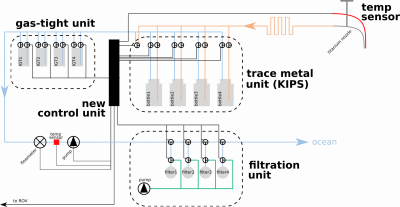

The foundation of the planned sampling system is the Kiel Pumping System (KIPS) developed by Dr. Dieter Garbe-Schönberg, University of Kiel. KIPS is an inert, temperature-resistant, modular, and remotely controlled fluid sampling system for the storage of 4 samples with up to 750 ml volume per ROV dive. In its current configuration, the systrm lacks the option of gas-tight fluid sampling and in situ filtration. In order to overcome these limitations, we are upgrading the existing 4-bottle KIPS system to include 4 additional sample bottles that are designed to allow for isobaric fluid sampling (gas-tight) as well as a filtration system, where a separately mounted peristaltic pump can be used for adding fixatives for subsequent biogeochemical analyses.

During ROV-based sampling, fluids enter the system via a titanium tube, that is guided by the ROV’s manipulator to the point of sampling. Sampled fluids are pumped through coiled PFA tubing (3/8” O.D., 6 m length) to the remotely controlled valve pack with 4 sample lines and 1 purge line. The sample lines could be used for different configurations such as filling either (i) individual sampling flasks of 750 mL and/or (ii) in situ filtration units for molecular microbiology. The KIPS gear pump (0-1 L/min) is mounted downstream and an in-line flow meter delivers real-time data for flow rate and total fluid volume. During MARUM ROV deployments, real-time temperature data for guiding the ROV pilots during fluid sampling is obtained by a high-temperature probe, which is mounted parallel to the titanium nozzle. Immediately after recovery of the ROV on deck all sample flasks are transferred to the ship’s laboratory for sub-sampling following standardized protocols.

The trace metal clean (former KIPS) system was successfully deployed during several MARUM ROV QUEST dives, (e.g. SO216, SO253 and former cruises on Mid-Atlantic Ridge systems during the SPP 1144 project) and guarantees the retrieval of uncontaminated samples from water depths of up to 5000 m. However, to date, the KIPS is not suitable for gas analyses in the vent fluid samples from the deep sea since samples are stored in non-gas-tight flasks. Furthermore, filtration is done only on board, which means that particles originally retrieved during pumping and particles formed during sample recovery cannot be distinguished.

The new sampling system will be modular and each sampling unit could be deployed individually or in combination with the one or both other modules. The three sampling modules will be equipped with a new control unit fit to allow for combined use with the ISMS such that a single inlet system (nozzle, T-probe, tubing) can be used for all types of hydrothermal vent fluid probing and sampling (see figure below). All modules will be remotely controlled via a new control unit, which needs to be fully integrated into the electrical, and software, control system of the MARUM ROV QUEST 4000 and ROV SQUID. This will allow fast and easy switching between (i) gas analyses by the ISMS for e.g. exploring and ecology studies, (ii) fluid sampling for e.g. chemical analyses, and (iii) fluid filtration for e.g. microbial analyses.

Technical Specifications

Physical Properties

- Weight in Air (kg): na

- Weight in SeaWater (kg): na

- Overall Dimensions (B x H x T mm): na

- Device is pressure isolated (450 bar pressure housing) and needs no hydraulic interfacing

Power Requirements

- Operating Voltage: 24V

- Operating Current: 3.5A

- Maximum Current (including startup): 5.5A

- Power Return(V-) is isolated from Chassis (GND)

Data Requirements

- Port Required: Ethernet

- Data Bits: 8

- Update rate: Continuous

Underwater Electric Interface Requirements

- All connectors can be installed (SeaNet available)

Topside Requirements

- Device needs lab (bench) space on ship and Laptop

- Topside Data Interface is PC-based

- Topside Data Interface needs TCP/IP

- Topside Interface is used for control and data retrieval

Expeditions

|

MSM109 |

Knipovich Ridge |

Contact

|

Jan Kleint |

|

|

Telefon: |

|

|

Fax: |

+49 421 218-65715 |