- Marine Engineering Geology

- Projects

- Vibro CPTu

Vibro CPTu

Topic

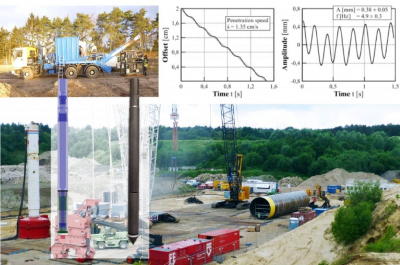

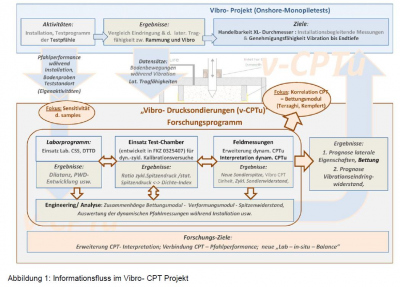

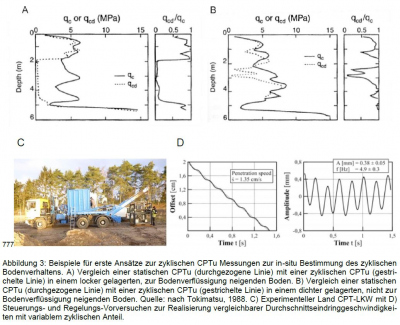

The project Vibro-CPTu stands for the development of an exploration method for the prediction of the lateral and axial carrying capacity of XL-Monopiles vibrated into the ground for the offshore wind industry.

Subproject: Device development for laboratory tests and field studies

Project Description

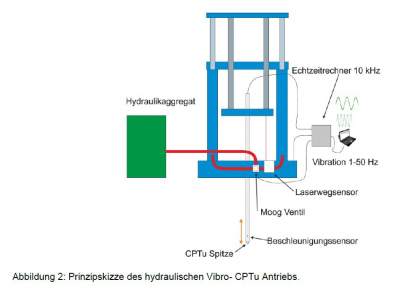

A high data-rate CPTu cone with real time capabilities will be developed and a commercial CPT rig will be upgraded for real-time controlled dynamic CPTu penetration allowing for stress, strain and energy controlled in situ experiments. This new tool will be used in cooperation with one project partner for soundings at the Vibro Pile Project test site at Cuxhaven and at other relevant sites with North Sea – like soil conditions.

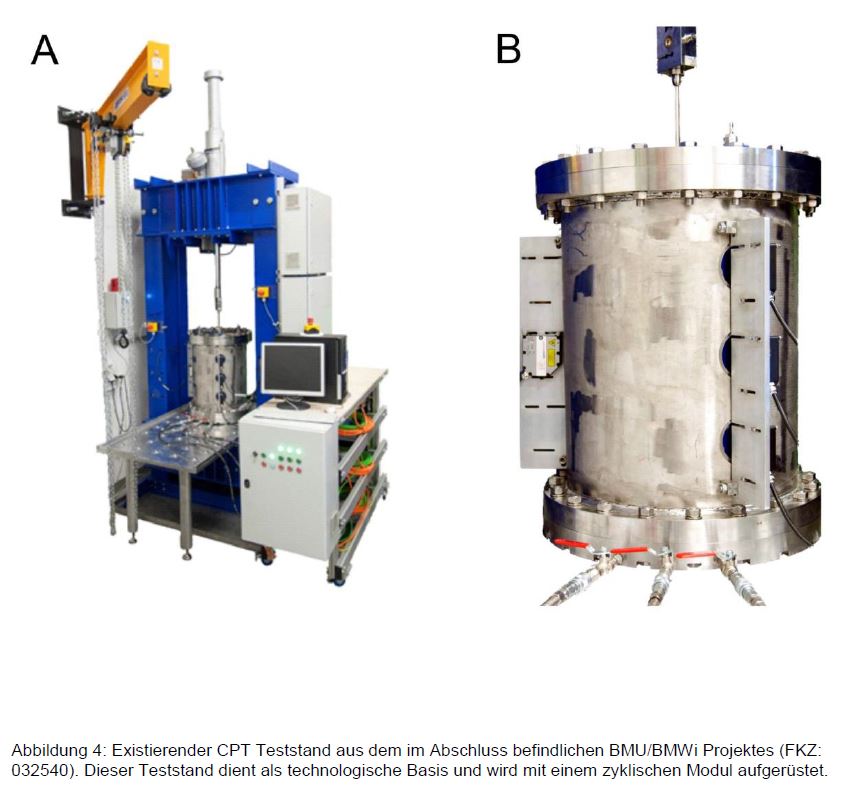

Furthermore will the existing CPT calibration chamber be modified and upgraded for Vibro CPT calibration tests. Then Vibro CPT calibration tests will be run in the upgraded chamber on reconstituted soil samples from the Vibro Pile test site at Cuxhaven, other North Sea like soil and also soil samples from drillings in the North Sea.

The reconstituted soil samples will be characterized with a cyclic, dynamic and static geotechnical lab program.

The Vibro CPTu field and lab data will be compared to the pile test data from the Vibro Pile Project and an optimal field testing and field data interpretation scheme will be developed in cooperation with the project partners.

Project Target

The overarching goal of the project is to gain more confidence and new means for the design and use of vibratory driven monopiles with diameters of up to at least six meters. The Vibro CPTu itself, which will be developed in this subproject, is an exploration tool to assess the soil behavior during and after vibratory pile driving. The Vibro CPTu is based on the existing knowledge of vibratory CPT, but extended with real-time controlled stress, strain or energy in situ experiments. These experiments will be calibrated with reconstituted sand with exactly defined properties and compared with the data form vibrated piles form the just finished “vibro pile project” at Cuxhaven. The results will be the base for the vibratory driving analysis, vibratory driving control and new design methods for lateral bearing capacity, which will be developed by the other project partners.

Joint Project

Project Coordination

MARUM, University Bremen

Project Lead: Dr. Stefan Kreiter

Address: Room 2230, Leobener Str. MARUM, 28359 Bremen, Germany

Phone: 0421- 218 65845

E-Mail: [Bitte aktivieren Sie Javascript]

Joint Partners

Fraunhofer-Institut für Windenergie und Energiesystemtechnik Nordwest (IWES)

Project Lead: Jan Hebig

Address: Am Fallturm 5, 28359 Bremen, Germany

Phone: 0421- 218 65804

E-Mail: [Bitte aktivieren Sie Javascript]

RWE Innogy GmbH (RWE-I)

Project Lead: Ben Matlock / Dr. Volker Herwig

Address: Überseering 34, 22297 Hamburg, Germany

Phone: +49 (0) 4020 9493 3056

E-Mail: [Bitte aktivieren Sie Javascript]

Vibro-Pile Konsortium (VPC)

Lead: RWE Innogy GmbH

Geo-Engineering.org GmbH (Geo-Eng)

Project Lead: Benjamin Ossig

Address: Am Fallturm 5/1, 28359 Bremen, Germany

Phone: 0421 69697780

E-Mail: [Bitte aktivieren Sie Javascript]