- Home

- Infrastructure

- Lab infrastructure

- Core Scanners & Loggers

- XRF Core Scanner

- FAQ - Frequently Asked Questions

- Core surface preparation

Core surface preparation

Sediment surface

The sediment surface should be as flat as possible.

A smooth surface of fine-grained sediments gives better results than a surface of sediment with bigger grains and therefore higher porosity (at some stage it does not make sense trying to analyze coarse or porous sediments).

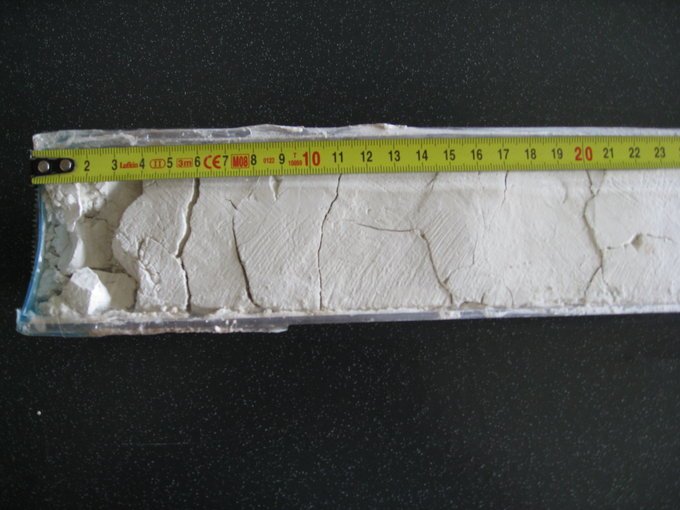

Cracks in the core should be logged and then skipped during the scan run.

Slightly bumpy or wavy sediment surfaces can be optimized by applying special tools trying to flatten the surface as best as possible.

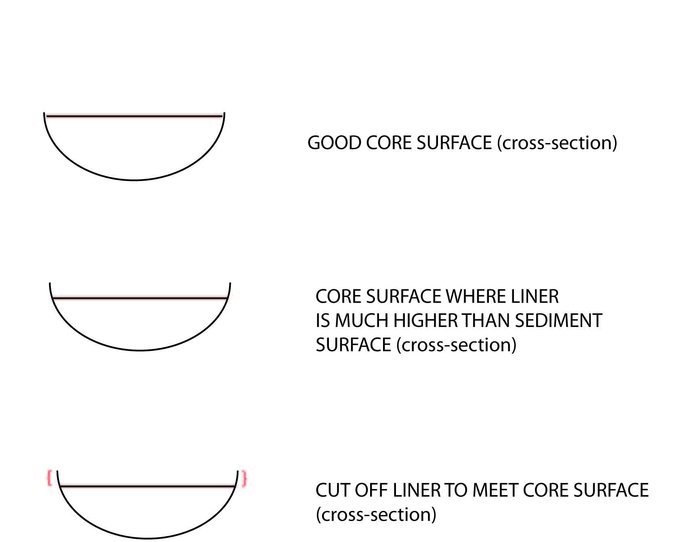

Liner

End caps

Please check how the end caps look like: carefully cut a little bit off if there is the risk that sharp ends sticking out would damage the lowering measurement unit.

Tools

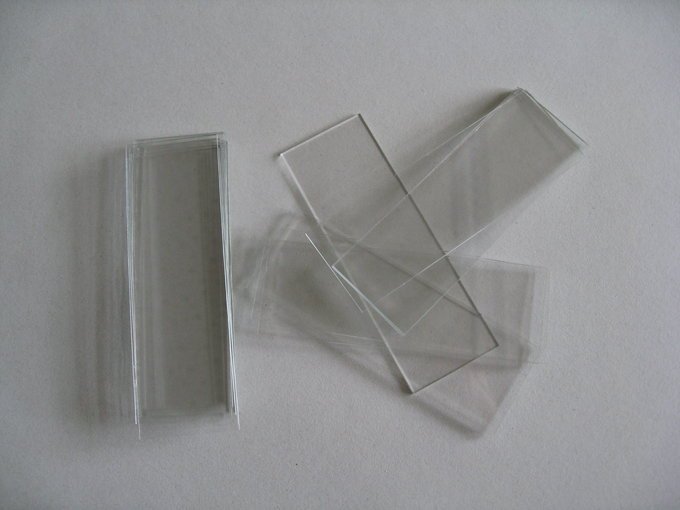

To avoid chemical or magnetic contamination of the sediment we only use glass slides for preparing the sediment surface of IODP/ODP/DSDP cores. Other cores might eventually be also treated with scarpers and knifes.

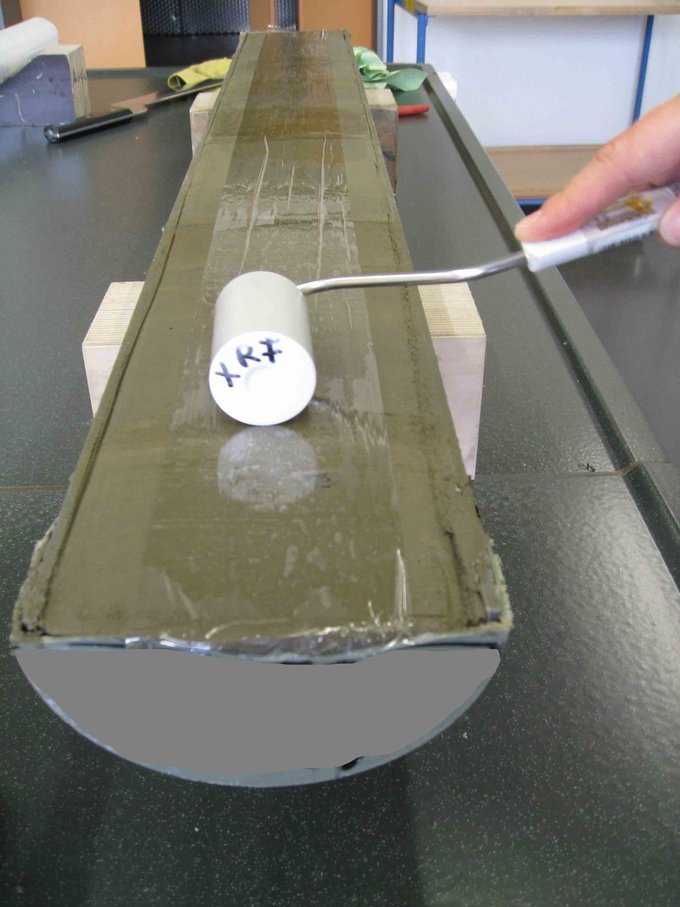

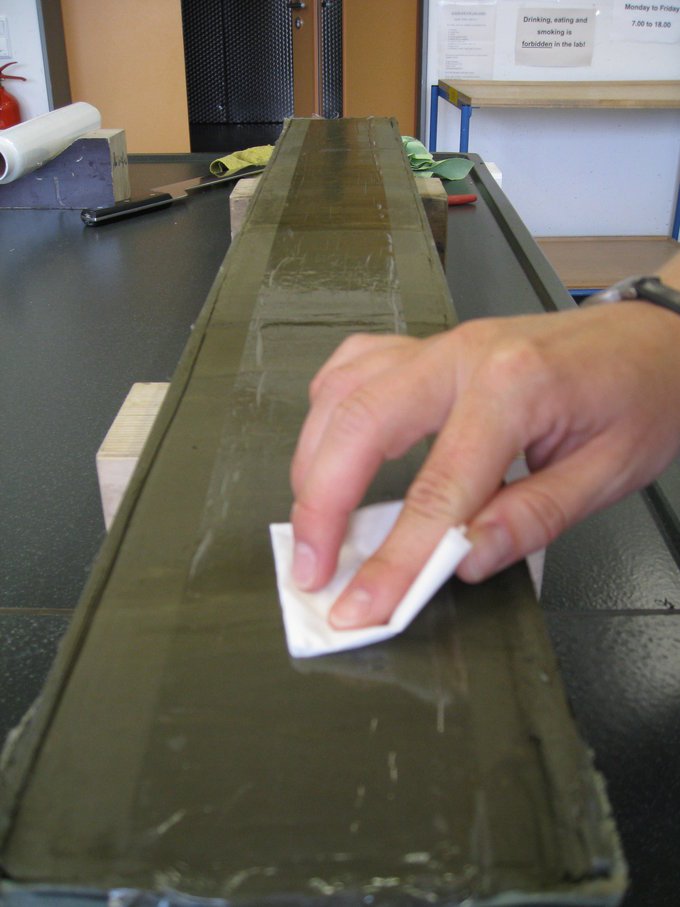

XRF foil

A special foil needs to be put on the core surface to avoid contamination. Please place the foil carefully and as accurate as possible on the sediment surface. Please also avoid (or at least to minimize) wrinkles or air bubbles. Tools like a roll or a lab tissue work best in helping to flatten the foil.

Placing the section in the scanner

Please measure and write down:

- the length of the core section,

- also note any additional potential measurement postions ("add")

- or measurement positions you need to avoid ("skip") like cracks and holes in the core surface.

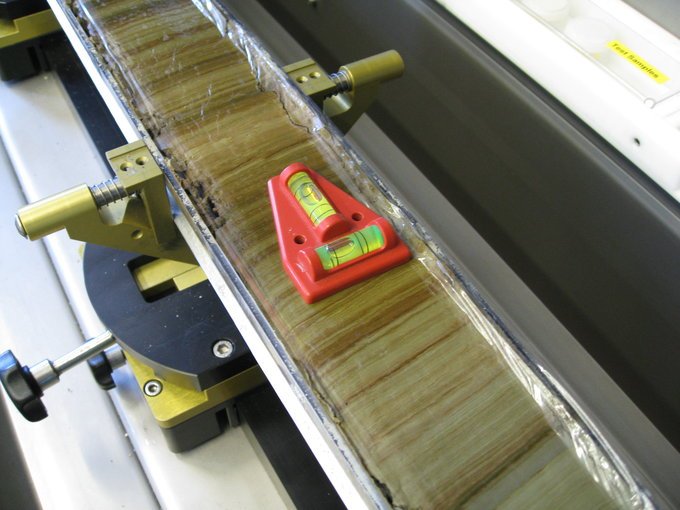

The core section needs to be placed horizontally into the holders of the scanner. A level helps to improve the adjustment.